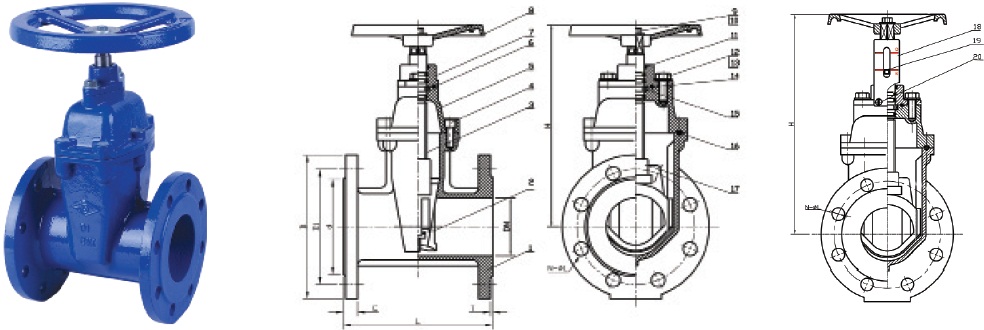

(Z45X) PN10/PN16/PN25

BS Standard Non-Rising Stem Resilient Wedge Gate Valves Type A T key (Z45X) PN10/PN16/PN25

Statement:

The gate valve can seal flow well with its soft wedge. Where the working temperature is ≤800C.They are widely used in architectonics, edibles, medicine, chemical energy, supplying and draining water industry, etc. It adjusts the water in piping line and in equipments.

Connection Ends:

BS EN 1092-2

Flange:BS EN 1092-2

Drive Style:

Lever handle

Electric drive

Pneumatic drive

Test Pressure:

PN10 Shell:1.5MPa Seal:1.1MPa

PN16 Shell:2.4MPa Seal:1.76MPa

PN25 Shell:3.75MPa Seal:2.75MPa

Applicable Temperature:

00C-800C

Surface:

150-500um,AWWA C550

Coating: Akzo Nobel Fusion Bonded Epoxy Coating with thickness 150-500um,Complies with ANSI/AWWA C550.

Applications:

Potable water, water supply and drainage, sewage disposal, irrigation air condition and fire protection pipe system etc.

Note: The first material is basic configuration. If you have different requirement on accessories, please remark it on inquiry.

Optional accessories: stem nut, electric drive, pneumatic drive, stem 2Cr13, stem 304, stem 316,brass thrust washer H62, brass thrust washer Hpb59-1, Indicator.

|

|

Part No.

|

Part

|

Specification

|

|

1

|

Valve Body

|

Ductile Iron QT450-10

|

|

2

|

Resilient Wedge Disc

|

Ductile Iron QT450-10/EPDM

|

|

3

|

Stem

|

Stainless Steel Cr13,304,316

|

|

4

|

Nut

|

Carbon Steel Zinc Plated

|

|

5

|

Bonnet

|

Ductile Iron QT450-10

|

|

6

|

O-Ring

|

NBR or EPDM

|

|

7

|

Gland Flange

|

Ductile Iron QT450-10

|

|

8

|

Handwheel

|

Ductile Iron QT450-10

|

|

9

|

Bolt

|

Carbon Steel Zinc Plated

|

|

10

|

Flat Washer

|

Carbon Steel Zinc Plated

|

|

11

|

Ring Wiper

|

NBR or EPDM

|

|

12

|

Bolt

|

Carbon Steel Zinc Plated

|

|

13

|

Flat Washer

|

Carbon Steel Zinc Plated

|

|

14

|

O-Ring

|

NBR or EPDM

|

|

15

|

Thrust Washer

|

Brass H62 or Hpb59-1

|

|

16

|

Bonnet Gasket

|

EPDM

|

|

17

|

Wedge Nut

|

Bronze ZQSn5-5-5

|

|

18

|

Indicator Board

|

Carbon Steel

|

|

19

|

Pointer

|

Cast Aluminium

|

|

20

|

Screw

|

Carbon Steel

|

|

|

|

|

|

Z45X

Flanged non-rising stem

gate valve with wheel and indicator |

Z45XC

Flanged non-rising stem

gate valve with stem cap |

Z35X

Mechanical joint non-rising stem

gate valve with wheel |

Z85X

Grooved non-rising stem

gate valve with wheel |

Features:

Akzo Nobel Fusion Bonded Epoxy Coating: Inside and Outside, can be used for potable water, food and pharmaceuticals industries with long life.

Material: Ductile Iron Body, Bonnet, Wedge and Handwheel, high strength and corrosion resisting. Valve seat cast with body at the same time, not necessary to machine.

Triple O-Ring stem seals make valves having axial self seals without the trouble of packing seal adjustment. The ring wiper can stop impurity going into shaft seal.

When valve is opened completely, It will have a smooth unobstructed waterway, without groove which will maintain sundries. The same O.D. will not affect fluid medium.

|

DN

|

PN

|

Dimensions (mm)

|

|

inch

|

mm

|

L

|

H

|

D

|

D1

|

d

|

C

|

T

|

N-φL

|

|

2”

|

50

|

10/16

|

178

|

218

|

165

|

125

|

99

|

19

|

3

|

4-Φ19

|

|

25

|

178

|

218

|

165

|

125

|

99

|

19

|

3

|

4-Φ19

|

|

2.5”

|

65

|

10/16

|

190

|

230

|

185

|

145

|

118

|

19

|

3

|

4-Φ19

|

|

25

|

190

|

230

|

185

|

145

|

118

|

19

|

3

|

8-Φ19

|

|

3”

|

80

|

10/16

|

203

|

281

|

200

|

160

|

132

|

19

|

3

|

8-Φ19

|

|

25

|

203

|

281

|

200

|

160

|

132

|

19

|

3

|

8-Φ19

|

|

4”

|

100

|

10/16

|

229

|

316

|

220

|

180

|

156

|

19

|

3

|

8-Φ19

|

|

25

|

229

|

316

|

235

|

190

|

156

|

19

|

3

|

8-Φ23

|

|

6”

|

150

|

10/16

|

267

|

420

|

285

|

240

|

211

|

19

|

3

|

8-Φ23

|

|

25

|

267

|

420

|

300

|

250

|

211

|

20

|

3

|

8-Φ28

|

|

8”

|

200

|

10

|

292

|

490

|

340

|

295

|

266

|

20

|

3

|

8-Φ23

|

|

16

|

292

|

490

|

340

|

295

|

266

|

20

|

3

|

12-Φ23

|

|

25

|

292

|

490

|

360

|

310

|

274

|

22

|

3

|

12-Φ28

|

|

10”

|

250

|

10

|

330

|

680

|

405

|

350

|

319

|

22

|

3

|

12-Φ23

|

|

16

|

330

|

680

|

405

|

355

|

319

|

22

|

3

|

12-Φ28

|

|

25

|

330

|

680

|

425

|

370

|

330

|

24.5

|

3

|

12-Φ31

|

|

12”

|

300

|

10

|

356

|

740

|

460

|

400

|

370

|

24.5

|

4

|

12-Φ23

|

|

16

|

356

|

740

|

460

|

410

|

370

|

24.5

|

4

|

12-Φ28

|

|

25

|

356

|

740

|

485

|

430

|

389

|

27.5

|

4

|

16-Φ31

|

|

14”

|

350

|

10

|

381

|

800

|

505

|

460

|

429

|

24.5

|

4

|

16-Φ23

|

|

16

|

381

|

800

|

520

|

470

|

429

|

26.5

|

4

|

16-Φ28

|

|

25

|

381

|

800

|

555

|

490

|

448

|

30

|

4

|

16-Φ34

|

|

16”

|

400

|

10

|

406

|

870

|

565

|

515

|

429

|

24.5

|

4

|

16-Φ28

|

|

16

|

406

|

870

|

580

|

525

|

480

|

28

|

4

|

16-Φ31

|

|

25

|

406

|

870

|

620

|

550

|

503

|

32

|

4

|

16-Φ37

|

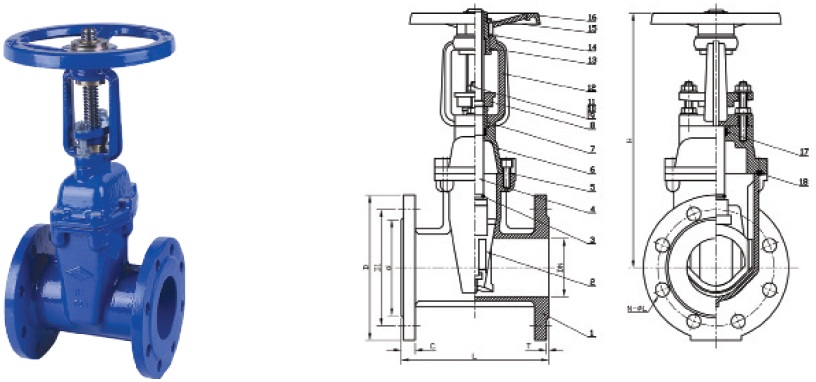

(Z41X) PN10/PN16/PN25

BS Standard Rising Stem Flanged Joint Ends Resilient Wedge Gate Valves (Z41X) PN10/PN16/PN25

Statement:

The gate valve can seal flow well with its soft wedge. Where the working temperature is ≤800C.They are widely used in architectonics, edibles, medicine, chemical energy, supplying and draining water industry, etc. It adjusts the water in piping line and in equipments.

Connection Ends:

BS EN 1092-2

Flange: BS EN 1092-2

Drive Style:

Lever handle

Electric drive

Pneumatic drive

Test Pressure:

PN10 Shell:1.5MPa Seal:1.1MPa

PN16 Shell:2.4MPa Seal:1.76MPa

PN25 Shell:3.75MPa Seal:2.75MPa

Applicable Temperature:

00C-800C

Surface:

150-500um,AWWA C550

Coating: Akzo Nobel Fusion Bonded Epoxy Coating with thickness 150-500um,Complies with ANSI/AWWA C550.

Applications:

Potable water, water supply and drainage, sewage disposal, irrigation air condition and fire protection pipe system etc.

|

|

Part No. |

Part |

Specification

|

|

1 |

Valve Body |

Ductile Iron QT450-10

|

|

2 |

Resilient Wedge Disc

|

Ductile Iron QT450-10/EPDM

|

|

3 |

Stem Back Seat O-Ring

|

EPDM |

|

4 |

Stem |

Stainless Steel Cr13,304,316

|

|

5 |

Nut |

Carbon Steel Zinc Plated

|

|

6 |

Bonnet |

Ductile Iron QT450-10

|

|

7 |

Stem Bushing |

Brass Hpb59-1 |

|

8 |

Gland |

Ductile Iron QT450-10

|

|

9 |

Flat Washer |

Carbon Steel Zinc Plated

|

|

10 |

Threaded Rod |

Carbon Steel Zinc Plated

|

|

11 |

Nut |

Carbon Steel Zinc Plated

|

|

12 |

Yoke |

Ductile Iron QT450-10

|

|

13 |

Stem Nut

|

Bronze ZQSn5-5-5 or Brass Hpb59-1

|

|

14 |

Washer |

Bronze ZQSn5-5-5 or Brass Hpb59-1

|

|

15 |

Locknut |

Malleable Iron KTH300-6 Zinc plated

|

|

16 |

Handwheel |

Ductile Iron QT450-10

|

|

17 |

O-Ring |

NBR or EPDM |

|

18 |

Bonnet Gasket |

EPDM |

|

|

|

|

Z41X

Flanged OS&Y gate valve |

Z81X

Grooved OS&Y gate valve |

Z51X

Flanged+Grooved OS&Y gate valve |

Note: The first material is basic configuration. If you have different requirement on accessories, please remark it on inquiry.

Optional accessories: electrical drive, pneumatic drive, stem 2Cr13, stem 304, stem 316, bronze stem nut ZQSn5-5-5、brass stem nut Hpb59-1.

|

DN

|

(PN)

|

Dimensions (mm)

|

|

inch

|

mm

|

L

|

H(close)

|

H1(open)

|

D

|

D1

|

d

|

C

|

T

|

N-φL

|

|

2”

|

50

|

10/16

|

178

|

257

|

307

|

165

|

125

|

99

|

19

|

3

|

4-Φ19

|

|

25

|

178

|

257

|

307

|

165

|

125

|

99

|

19

|

3

|

4-Φ19

|

|

2.5”

|

65

|

10/16

|

190

|

305

|

370

|

185

|

145

|

118

|

19

|

3

|

4-Φ19

|

|

25

|

190

|

305

|

370

|

185

|

145

|

118

|

19

|

3

|

8-Φ19

|

|

3”

|

80

|

10/16

|

203

|

350

|

430

|

200

|

160

|

132

|

19

|

3

|

8-Φ19

|

|

25

|

203

|

350

|

430

|

200

|

160

|

132

|

19

|

3

|

8-Φ19

|

|

4”

|

100

|

10/16

|

229

|

422

|

522

|

220

|

180

|

156

|

19

|

3

|

8-Φ19

|

|

25

|

229

|

422

|

522

|

235

|

190

|

156

|

19

|

3

|

8-Φ23

|

|

6”

|

150

|

10/16

|

267

|

563

|

713

|

285

|

240

|

211

|

19

|

3

|

8-Φ23

|

|

25

|

267

|

563

|

713

|

300

|

250

|

211

|

20

|

3

|

8-Φ28

|

|

8”

|

200

|

10

|

292

|

675

|

875

|

340

|

295

|

266

|

20

|

3

|

8-Φ23

|

|

16

|

292

|

675

|

875

|

340

|

295

|

266

|

20

|

3

|

12-Φ23

|

|

25

|

292

|

675

|

875

|

360

|

310

|

274

|

22

|

3

|

12-Φ28

|

|

10”

|

250

|

10

|

330

|

930

|

1180

|

405

|

350

|

319

|

22

|

3

|

12-Φ23

|

|

16

|

330

|

930

|

1180

|

405

|

355

|

319

|

22

|

3

|

12-Φ28

|

|

25

|

330

|

930

|

1180

|

425

|

370

|

330

|

24.5

|

3

|

12-Φ31

|

|

12”

|

300

|

10

|

356

|

1050

|

1350

|

460

|

400

|

370

|

24.5

|

4

|

12-Φ23

|

|

16

|

356

|

1050

|

1350

|

460

|

410

|

370

|

24.5

|

4

|

12-Φ28

|

|

25

|

356

|

1050

|

1350

|

485

|

430

|

389

|

27.5

|

4

|

16-Φ31

|

Features:

Akzo Nobel Fusion Bonded Epoxy Coating: Inside and Outside, can be used for potable water, food and pharmaceuticals industries with long life.

Material: Ductile Iron Body, Bonnet, Wedge and Handwheel, high strength and corrosion resisting. Valve seat cast with body at the same time, not necessary to machine. When valve is opened completely, It will have a smooth unobstructed waterway, without groove which will maintain sundries. The same O.D. will not

affect fluid medium.

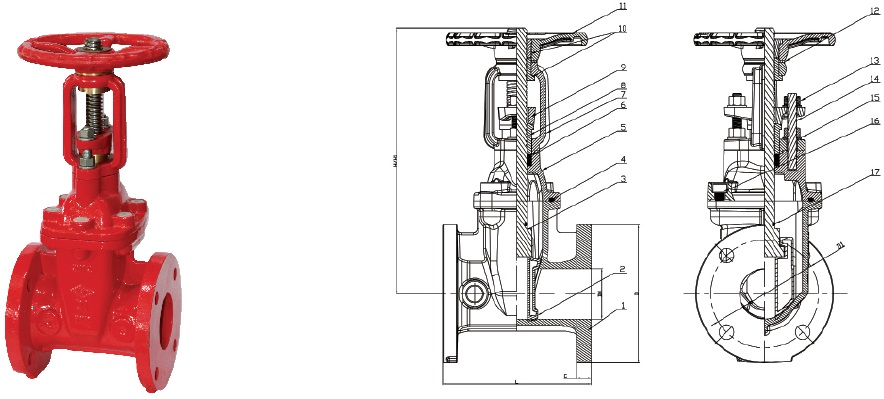

(Z41X) 250PSI/300PSI

Statement:

The gate valve can seal flow well with its soft wedge. Where the working temperature is ≤800C.They are widely used in architectonics, edibles, medicine,chemical energy, supplying and draining water industry, etc. It adjusts the water in piping line and in equipments.

Connection Ends:

ASME B16.1

Flange: ASME B16.1

Drive Style:

Lever handle

Electric drive

Pneumatic drive

Test Pressure:

250PSI Shell:500PSI Seal:250PSI

300PSI Shell:600PSI Seal:300PSI

Applicable Temperature:

00C-800C

Surface:

150-500um,AWWA C550

Coating: Akzo Nobel Fusion Bonded Epoxy Coating with thickness 150-500um,Complies with ANSI/AWWA C550.

Applications:

Potable water, water supply and drainage, sewage disposal, irrigation air condition and fire protection pipe system etc.

American Standard Rising Stem Flanged Joint Ends Resilient Wedge Gate Valves

|

|

Part No.

|

Part

|

Specification

|

|

1

|

Valve Body

|

Ductile Iron QT450-10

|

|

2

|

Resilient Wedge Disc

|

Ductile Iron QT450-10/EPDM

|

|

3

|

Stem

|

Stainless Steel Cr13,304,316

|

|

4

|

Bonnet Gasket

|

EPDM

|

|

5

|

Bonnet

|

Ductile Iron QT450-10

|

|

6

|

O-Ring

|

NBR or EPDM

|

|

7

|

Yoke

|

Ductile Iron QT450-10

|

|

8

|

Stem Bushing

|

Hpb59-1

|

|

9

|

Gland

|

Ductile Iron QT450-10

|

|

10

|

Stem Nut

|

Bronze ZQSn5-5-5 or Brass Hpb59-1

|

|

11

|

Handwheel

|

Ductile Iron QT450-10

|

|

12

|

Washer

|

Bronze ZQSn5-5-5 or Brass Hpb59-1

|

|

13

|

Nut

|

Carbon Steel Zinc Plated

|

|

14

|

Threaded Rod

|

Carbon Steel Zinc Plated

|

|

15

|

Flat Washer

|

Carbon Steel Zinc Plated

|

|

16

|

Bolt

|

Carbon Steel Zinc Plated

|

|

17

|

Stem Back Seat O-Ring

|

EPDM

|

|

|

|

|

Z41X

Flanged OS&Y gate valve |

Z81X

Grooved OS&Y gate valve |

Z51X

Flanged+Grooved OS&Y gate valve |

Note: The first material is basic configuration. If you have different requirement on accessories, please remark it on inquiry.

Optional accessories: electrical drive, pneumatic drive, stem 2Cr13, stem 304, stem 316, bronze stem nut ZQSn5-5-5、brass stem nut Hpb59-1.

Features:

Akzo Nobel Fusion Bonded Epoxy Coating: Inside and Outside, can be used for potable water, food and pharmaceuticals industries with long life.

Material: Ductile Iron Body, Bonnet, Wedge and Handwheel, high strength and corrosion resisting. Valve seat cast with body at the same time, not necessary to machine. When valve is opened completely, It will have a smooth unobstructed waterway, without groove which will maintain sundries. The same O.D. will not

affect fluid medium.

|

DN

|

Dimensions(mm)

|

|

inch

|

mm

|

L

|

H(open)

|

H1(close)

|

D

|

D1

|

C

|

n-φL

|

|

2"

|

50

|

178

|

370

|

318

|

152

|

102.7

|

16

|

4-Φ19.1

|

|

2.5"

|

65

|

190

|

410

|

343

|

178

|

139.7

|

17.5

|

4-Φ19.1

|

|

3"

|

80

|

203

|

468

|

386

|

191

|

152.4

|

19

|

8-Φ19.1

|

|

4"

|

100

|

229

|

538

|

436

|

229

|

190.5

|

19

|

8-Φ19.1

|

|

5"

|

125

|

254

|

640

|

513

|

254

|

215.9

|

19.1

|

8-Φ22.2

|

|

6"

|

150

|

267

|

730

|

576

|

279

|

241.3

|

19.1

|

8-Φ22.2

|

|

8"

|

200

|

292

|

950

|

749

|

343

|

298.5

|

22.2

|

8-Φ22.2

|

|

10"

|

250

|

330

|

1158

|

904

|

406

|

362

|

23.8

|

12-Φ25.4

|

|

12"

|

300

|

356

|

1335

|

1030

|

483

|

431.8

|

25.4

|

12-Φ25.4

|

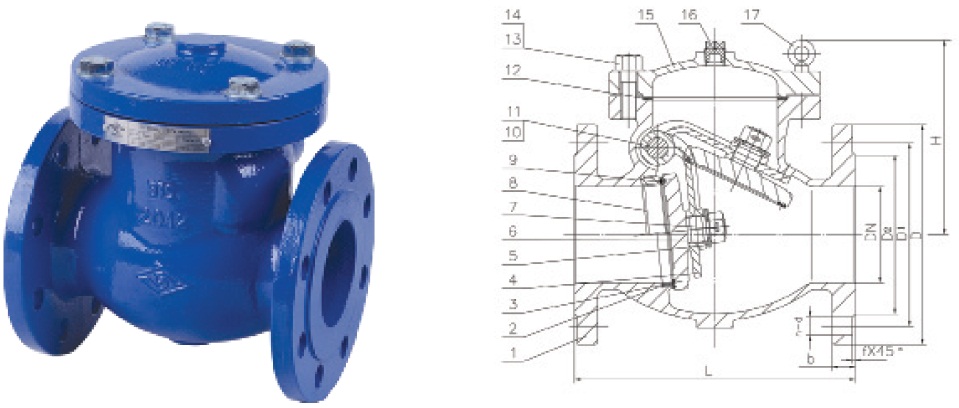

Usage: It can prevent the water from flowing backward.

Connection Ends:

BS EN 1092-2

Flange: BS EN 1092-2

Rubber Seal:

Test Pressure:

PN10 Shell:1.5MPa Seal:1.1MPa

PN16 Shell:2.4MPa Seal:1.76MPa

PN25 Shell:3.75MPa Seal:2.75MPa

Applicable Temperature:

00C-800C

Metal Seal:

Test Pressure:

PN10 Shell:1.5MPa Seal:1.1MPa

PN16 Shell:2.4MPa Seal:1.76MPa

PN25 Shell:3.75MPa Seal:2.75MPa

Applicable Temperature:

-100C—3500C

Surface:

150-500um,AWWA C550

Coating: Akzo Nobel Fusion Bonded Epoxy Coating with thickness 150-500um,Complies with ANSI/AWWA C550.

Applications:

Potable water, water supply and drainage.

sewage disposal, irrigation and fire protection, steam and oil pipe system etc.

BS Standard Swing Check Valves Flanged Joint Ends,

Rubber Seal (H44X) / Metal Seal (H44T) PN10/PN16/PN25

|

|

Part No.

|

Part

|

Specification

|

|

1

|

Valve Body

|

Ductile Iron QT450-10

|

|

2

|

Seat Ring (press fit)

|

ASTM B62 or 13Cr

|

|

3

|

Disc

|

Ductile Iron QT450-10 and EPDM

Ductile Iron QT450-10 and Seat Ring

|

|

4

|

Hinge

|

Ductile Iron QT450-10

|

|

5

|

Washer

|

Stainless Steel 13Cr

|

|

6

|

Nut

|

Carbon Steel Zinc Plated

|

|

7

|

Split Pin

|

Stainless Steel 304

|

|

8

|

Seat Ring Threaded

|

Brass ASTM B62 or

Stainless Steel13Cr

|

|

9

|

Disc Seal Ring

|

ASTM B62 or 13Cr

|

|

10

|

Hinge Pin

|

Stainless Steel 13Cr

|

|

11

|

Plug

|

Malleable Iron Galvanized

|

|

12

|

Bonnet Gasket

|

Graphite + Steel

EPDM

|

|

13

|

Bolts

|

Carbon Steel Zinc Plated

|

|

14

|

Washer

|

Carbon Steel Zinc Plated

|

|

15

|

Bonnet

|

Ductile Iron QT450-10

|

|

16

|

Plug

|

Malleable Iron Galvanized

|

|

17

|

Sling Ring

|

Carbon Steel Zinc Plated

|

|

Features:

Light body, short on & off distance for disc, small flow resistance. Valve can be stopped quickly with good energy-saving results.

|

DN

|

PN

|

Dimensions (mm)

|

|

inch

|

mm

|

L

|

D

|

D1

|

D2

|

b

|

n-d

|

f

|

H

|

|

2”

|

50

|

10/16/25

|

203

|

165

|

125

|

99

|

19

|

4-19

|

3

|

146

|

|

2.5”

|

65

|

10/16/25

|

216

|

185

|

145

|

118

|

19

|

4-19

|

3

|

155

|

|

3”

|

80

|

10/16/25

|

241

|

200

|

160

|

132

|

19

|

8-19

|

3

|

173

|

|

4”

|

100

|

10/16

|

292

|

220

|

180

|

156

|

19

|

8-19

|

3

|

180

|

|

25

|

292

|

235

|

190

|

156

|

19

|

8-23

|

3

|

180

|

|

5”

|

125

|

10/16

|

330

|

250

|

210

|

184

|

19

|

8-19

|

3

|

212

|

|

25

|

330

|

270

|

220

|

184

|

19

|

8-23

|

3

|

212

|

|

6”

|

150

|

10/16

|

356

|

285

|

240

|

211

|

19

|

8-23

|

3

|

260

|

|

25

|

356

|

300

|

250

|

211

|

20

|

8-28

|

3

|

260

|

|

8”

|

200

|

10

|

495

|

340

|

295

|

266

|

20

|

8-23

|

3

|

290

|

|

16

|

495

|

340

|

295

|

266

|

20

|

12-23

|

3

|

290

|

|

25

|

495

|

360

|

310

|

274

|

22

|

12-28

|

3

|

290

|

|

10”

|

250

|

10

|

622

|

405

|

350

|

319

|

22

|

12-23

|

3

|

339

|

|

16

|

622

|

405

|

355

|

319

|

22

|

12-28

|

3

|

339

|

|

25

|

622

|

425

|

370

|

330

|

24.5

|

12-31

|

3

|

339

|

|

12”

|

300

|

10

|

698

|

460

|

400

|

370

|

24.5

|

12-23

|

4

|

376

|

|

16

|

698

|

460

|

410

|

370

|

24.5

|

12-28

|

4

|

376

|

|

25

|

698

|

485

|

430

|

389

|

27.5

|

16-31

|

4

|

376

|

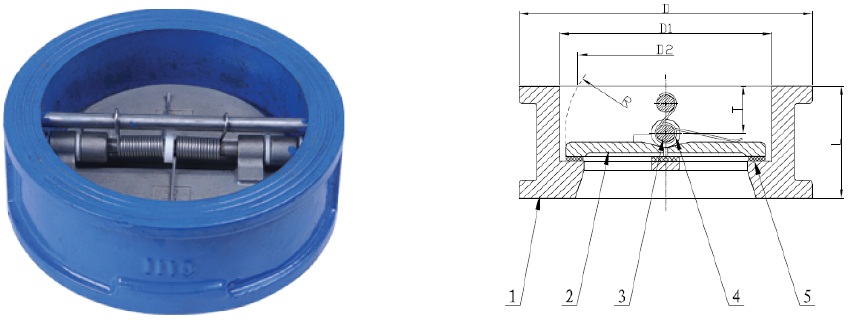

(DH77X) PN10/PN16

BS Standard Wafer Butterfly-type Check Valves (DH77X) PN10/PN16

Statement:

The valve can be used on pipe line through which water ≤800C or other noncorrosive

medium to prevent back flow.

Test Pressure:

PN10 Shell:1.5MPa Seal:1.1MPa

PN16 Shell:2.4MPa Seal:1.76MPa

Applicable Temperature:

00C-800C

Surface:

150-500um,AWWA C550

Coating: Akzo Nobel Fusion Bonded Epoxy Coating with thickness 150-500um,Complies with ANSI/AWWA C550.

Applications:

To prevent the medium regorging and diminish noises of potable water, water supply and drainage, sewage disposal, irrigation and fire protection pipe system etc.

|

|

Part No.

|

Part

|

Specification

|

|

1

|

Valve Body

|

Ductile Iron QT450-10

|

|

2

|

Disc

|

Ductile Iron QT450-10 Zinc Plated or Stainless Steel 304

|

|

3

|

Stem

|

Stainless Steel

|

|

4

|

Spring

|

Stainless Steel

|

|

5

|

Rubber Seat

|

EPDM or NBR

|

|

Optional accessories: ductile iron disc or stainless steel 304 disc.

Features:

Accelerate closing by lighter body design and use of spring, can reduce the water hammer and sound.

Short distance between valve's surface than the general check valve makes installation becoming easier in the limit

space.

Small size, light weight, reasonable constructure, easy maintenance.

Can be installed in horizontal or vertical direction pipeline. The valve stem should be perpendicular to the flow direction when installed into horizontal pipeline. On vertical pipeline, the flow direction should be from the bottom to up.

Akzo Nobel Fusion Bonded Epoxy Coating: Inside and Outside, can be used for potable water, food and pharmaceuticals industries with long life.

|

DN

|

PN

|

Dimensions (mm)

|

|

inch |

mm |

L

|

D

|

D1

|

D2

|

R

|

t

|

|

2” |

50

|

PN10/16

|

54

|

107

|

64

|

41.6

|

28.5

|

19.5

|

|

2.5” |

65

|

PN10/16

|

54

|

127

|

78

|

36.6

|

36

|

31

|

|

3” |

80

|

PN10/16

|

57

|

142

|

94

|

67.5

|

42

|

25

|

|

4” |

100

|

PN10/16

|

64

|

162

|

117

|

83.5

|

50

|

27.5

|

|

5” |

125

|

PN10/16

|

70

|

192

|

145

|

116

|

66

|

31.5

|

|

6” |

150

|

PN10/16

|

76

|

218

|

170

|

140.5

|

77

|

31.5

|

|

8” |

200

|

PN10/16

|

95

|

273

|

224

|

189.2

|

102.5

|

39.5

|

|

10” |

250

|

PN10/16

|

108

|

328

|

265

|

233.7

|

125

|

44.5

|

|

12” |

300

|

PN10/16

|

143

|

378

|

310

|

203.6

|

146

|

72.5

|

|

14” |

350

|

PN10/16

|

127

|

438

|

360

|

327.87

|

170

|

45

|

|

16” |

400

|

PN10/16

|

140

|

489

|

410

|

375.88

|

195

|

52

|

|

18” |

450

|

PN10/16

|

152

|

555

|

450

|

414.06

|

215

|

58

|

|

20” |

500

|

PN10/16

|

152

|

594

|

505

|

467.83

|

241

|

58

|

|

24” |

600

|

PN10/16

|

178

|

700

|

624

|

569.59

|

294

|

73

|

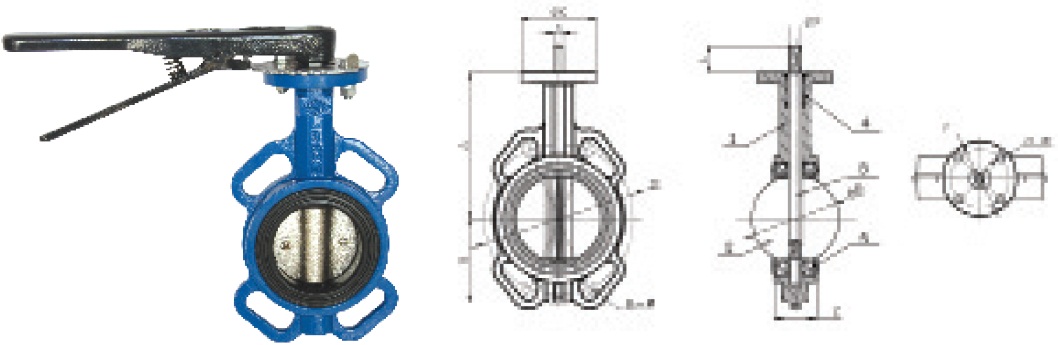

(D71X) PN6/PN10/PN16

Wafer Butterfly Valves (D71X) PN6/PN10/PN16

Statement:

The valve is widely applied to cut off fluid in piping system. It can also be designed, however, to act as adjusting valve or with both functions.

Standard:

BS 5155

ISO5211

Top flange standard: ISO5211

Drive Style:

Lever handle

Gear handle

Electric drive

Pneumatic drive

Test Pressure:

PN6 Shell:0.9Mpa Seal:0.66MPa

PN10 Shell:1.5MPa Seal:1.1MPa

PN16 Shell:2.4MPa Seal:1.76MPa

Applicable Temperature:

00C-800C

Surface:

150-500um, AWWA C550

Coating: Akzo Nobel Fusion Bonded Epoxy

Coating with thickness 150-500um, Complies with ANSI/AWWA C550.

Applications:

Potable water, water supply and drainage, sewage disposal, irrigation and fire

protection pipe system etc.

|

|

Part No.

|

Part

|

Specification

|

|

1

|

Valve Body

|

Ductile Iron QT450-10

|

|

2

|

Disc

|

Ductile Iron QT450-10 Zinc Plated

Ductile Iron QT450-10 Nickel Plated

Stainless Steel CF8

Carbon Steel

Stainless Steel CF8M

|

|

3

|

Stem

|

Stainless Steel

|

|

4

|

Bushing

|

NYLON 1010

|

|

5

|

Rubber Seat

|

EPDM

NBR

|

|

|

|

|

|

D71X

Wafer butterfly valve

lever handle |

D371X

Wafer butterfly valve

gear handle |

D971X

Wafer butterfly valve

electric drive |

D671X

Wafer butterfly valve

pneumatic drive |

|

DN

|

Dimensions (mm)

|

|

inch

|

mm

|

A

|

B

|

C

|

D

|

D1

|

L

|

K

|

E

|

Φ2

|

n1-Φ1

|

n-Φ

|

G

|

|

1.0

|

1.6

|

1.0

|

1.6

|

|

2"

|

50

|

140.5

|

64.5

|

43

|

53.9

|

125

|

125

|

32

|

90

|

70

|

14

|

4-Φ10

|

4-Φ19

|

4-Φ19

|

9.53

|

|

2.5"

|

65

|

153

|

72

|

46

|

65.2

|

145

|

145

|

32

|

90

|

70

|

14

|

4-Φ10

|

4-Φ19

|

4-Φ19

|

9.53

|

|

3"

|

80

|

153

|

86

|

46

|

79.7

|

160

|

160

|

32

|

90

|

70

|

14

|

4-Φ10

|

8-Φ19

|

8-Φ19

|

9.53

|

|

4"

|

100

|

176

|

100

|

52

|

105

|

180

|

180

|

32

|

90

|

70

|

16

|

4-Φ10

|

8-Φ19

|

8-Φ19

|

11.14

|

|

5"

|

125

|

191

|

112

|

56

|

130

|

210

|

210

|

32

|

90

|

70

|

16

|

4-Φ10

|

8-Φ19

|

8-Φ19

|

11.14

|

|

6"

|

150

|

202.5

|

128

|

56

|

155.8

|

240

|

240

|

32

|

90

|

70

|

20

|

4-Φ10

|

8-Φ23

|

8-Φ23

|

12.7

|

|

8"

|

200

|

243.5

|

162

|

60

|

206.7

|

295

|

295

|

45

|

125

|

102

|

26

|

4-Φ12

|

8-Φ23

|

12-Φ23

|

20.6

|

|

10"

|

250

|

273

|

194

|

68

|

253.25

|

350

|

355

|

45

|

125

|

102

|

26

|

4-Φ12

|

12-Φ23

|

12-Φ28

|

20.6

|

|

12"

|

300

|

311

|

223

|

78

|

301.85

|

400

|

410

|

45

|

125

|

102

|

28

|

4-Φ12

|

12-Φ23

|

12-Φ28

|

22.1

|

|

14"

|

350

|

368

|

267

|

76.5

|

333.3

|

460

|

470

|

45

|

125

|

102

|

31.6

|

4-Φ12

|

16-Φ23

|

16-Φ28

|

22.1

|

|

16"

|

400

|

400

|

307

|

86.5

|

389.6

|

515

|

525

|

51.2

|

175

|

140

|

33.15

|

4-Φ18

|

16-Φ28

|

16-Φ31

|

22.1

|

|

18"

|

450

|

422

|

328

|

105.6

|

440.5

|

565

|

585

|

51.2

|

175

|

140

|

38

|

4-Φ18

|

20-Φ28

|

20-Φ31

|

27

|

|

20"

|

500

|

480

|

361

|

131.8

|

491.6

|

620

|

650

|

64.2

|

175

|

140

|

41.15

|

4-Φ18

|

20-Φ28

|

20-Φ34

|

27

|

|

24"

|

600

|

562

|

459

|

152

|

592.5

|

725

|

770

|

70.2

|

210

|

165

|

50.65

|

4-Φ22

|

20-Φ31

|

20-Φ37

|

36

|

|

28"

|

700

|

624

|

520

|

163

|

695

|

840

|

840

|

66

|

300

|

254

|

63.5

|

4-Φ18

|

24-Φ31

|

24-Φ37

|

46

|

|

32"

|

800

|

672

|

591

|

188

|

794.7

|

950

|

950

|

66

|

300

|

254

|

63.5

|

4-Φ18

|

24-Φ34

|

24-Φ41

|

46

|

|

36"

|

900

|

720

|

656

|

203

|

864.7

|

1050

|

1050

|

118

|

300

|

254

|

75

|

4-Φ18

|

28-Φ34

|

28-Φ41

|

55

|

|

40"

|

1000

|

800

|

721

|

216

|

965

|

1160

|

1170

|

253

|

300

|

254

|

85

|

4-Φ18

|

28-Φ37

|

28-Φ44

|

55

|

Features:

Small size with light weight design, easy installation and

maintenance wherever required.

Simple and compact construction, quick 90 degrees on-off operation. when it's closed, no leakage under pressure testing.

Minimized operating torque, light force required during operating. Flow curve tending to straight line. Excellent reguloting performance. Long service life, capable of withstanding 10,000 times of on-off testing. Widely used for various medium with different accessories.

Akzo Nobel Fusion Bonded Epoxy Coating: Inside and Outside, can be used for potable water, food and pharmaceuticals industries with long life.

|